“ Thank you for elevating my understanding of inkjet technology! Now, I can relate waveforms, satellite formation and gray scaling with a straight coherent face! ”

Bruk Sahilu, Nike

“ ESMA Academy courses offer an exceptional blend of theory and hands-on practice, creating a friendly yet professional atmosphere where participants can deepen their understanding of inkjet technology. ”

Pegah Shakeri, Kuraray Europe

“ This course is excellent for those who want to discover the basics of the digital printer, mechanical construction, chemical and physics topics. ”

Wouter Malfait, Van Dam Machine

“ The course gave a great overview of the whole inkjet process chain. A special highlight for me was the insightful deep dive into the inkjet physics. ”

Stefan Schlisske, Nano Dimension

“ Inkjet training, from clueless to confident! ”

Aymeric Champion, RadLab

“ No matter your experience or knowledge level in inkjet, there's always something new to learn. The Academy was a fantastic opportunity to connect with both new and familiar faces in the industry, exchange insights, and grow through shared experiences. ”

Richard Fisher, Fujifilm Ink Solutions

ESMA Academy - Inkjet Applications: Metal

Know-how transfer and hands-on training8-11 December 2025, Selb – Germany

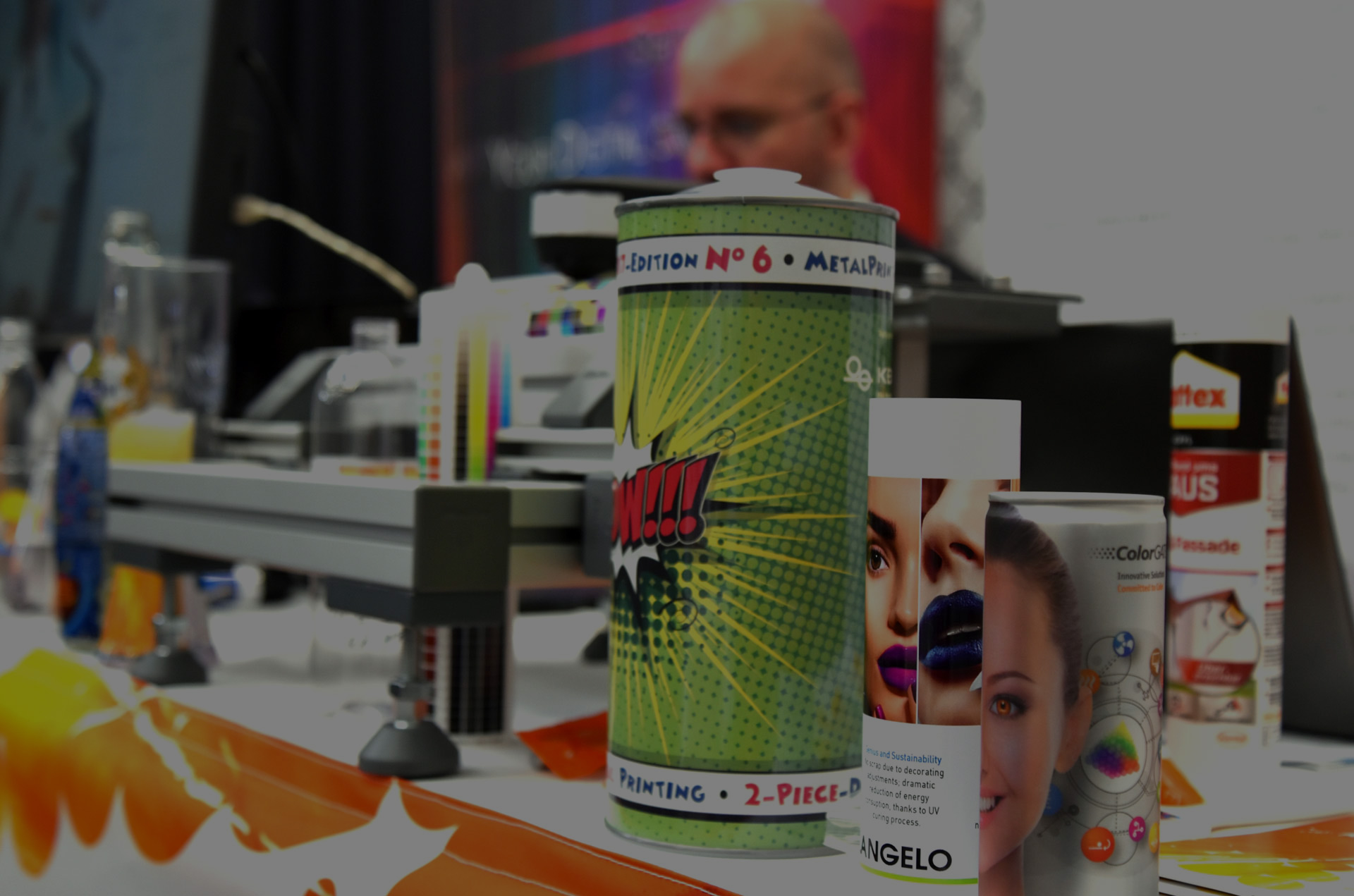

Inkjet for metal

From beverage cans and bottle caps to decorative panels, nameplates, automotive or aeromotive parts, electronics housings, and architectural elements – inkjet printing is increasingly adopted as a high-quality, digital decoration and marking solution for metal surfaces. Whether working with aluminium, stainless steel, coated metals or specialty alloys, the technology continues to evolve to meet industrial demands. ESMA Academy explores how inkjet offers sustainable, precise, and customisable output on a variety of metal substrates. We delve into key considerations such as pre-treatment methods, ink formulations, print system architecture and colour management.

Comprehensive content

Where does surface tension come from? How can I qualify substrates quickly? How long will pre-treatment last? How to achieve stronger ink adhesion? Which printhead will best fit my substrate’s shape? UV, water-based or solvent inks? Heat curing, UV-LED or infrared drying? How far are we in robotics integration? The course starts with a thorough overview of inkjet chemistry and physics. During lab-based sessions participants experiment with pre-treatment methods, ink characterisation, print parameters, ink delivery systems, drying and curing mechanisms, print quality, drop and colour management. The last part demonstrates problem solving and points to best practices, shows influential market drivers and latest industry patents, opens room for final discussions, and makes sure that no questions are left unanswered.

Who should attend

Whether you have already integrated inkjet printing into your production line or are just exploring its potential, ESMA Academy will guide you through every step toward a highly efficient metal decoration process. We welcome metal part and component manufacturers, can and tube producers, appliance and automotive suppliers, metal packaging converters, OEMs, system integrators, ink and coating suppliers, brand owners, and all those impacted by the digital transformation in metal decoration to benefit from this course. Prepared and delivered by leading experts in print technology, the course provides essential knowledge to support investment, innovation, and integration decisions.

Programme

Date: 8-11 December 2025, Selb, Germany

Monday, 08/12/25

13:00-13:30 Lunch and welcome

13:30-15:00 Inkjet chemistry overview

15:00-16:30 Inkjet physics overview

16:30-17:30 Fluid delivery

17:30-18:00 Technology ecosystem

Tuesday, 09/12/25

09:00-10:00 Pre-treatment

10:00-11:00 Printheads, ink characterisation and functionality, filtration

11:00-12:00 Drop watching

12:00-13:00 Lunch break

13:00-17:30 Practice sessions in groups: Surface treatment, Ink characterisation and filtration, Ink supply and drop watching

18:00 Social evening

Wednesday, 10/12/25

09:00-09:40 Ink formulation

09:40-10:20 UV curing

10:20-11:00 (N)IR drying

11:00-12:00 Image quality and colour management

12:00-13:00 Lunch break

13:00-17:30 Practice sessions in groups: UV curing, (N)IR drying, colour management

Thursday, 11/12/25

09:00-10:00 Patents and innovations, market and trends outlook

10:00-10:30 Perspectives of the metal industry

10:30-11:00 Sustainability

11:00-12:00 Problem solving and open discussion

12:00-13:00 Certificates and (take-away) lunch

ESMA Academy

Inkjet Applications: Metal

Know-how transfer and hands-on training

Date: 8-11 December 2025

Location: The course takes place in the European Centre for Dispersion Technologies, Selb, Germany

Participation fee: 2.350 EUR